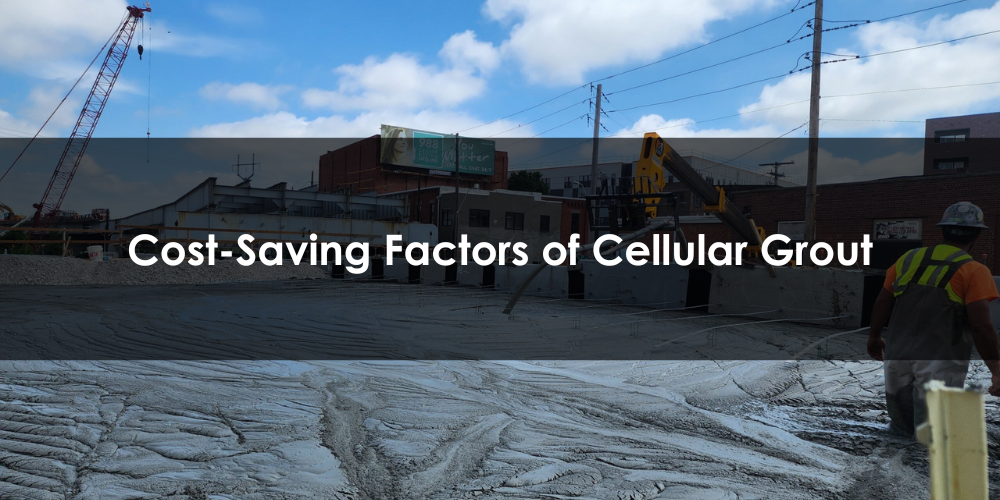

Cellular grout, also called low-density cellular concrete or flowable fill, is a common material option for void fills and wall backfills. There are several benefits to LDCC, including reduced construction time, materials, and labor, that can contribute to long-term project cost savings.

In this blog post, our team of engineered fill experts explain six ways cellular grout is cost-effective.

#1: Self-leveling

Cellular grout is made of cement, water, fly ash or sand, and uniformly distributed air bubbles. This unique composition creates a lightweight, flowable material that spreads and settles fairly evenly, without the need for manual rolling and leveling. This saves man hours and equipment cost during the installation process.

#2: Self-compacting and quick-drying

Traditional fill requires a tamping/compaction machine, multiple lifts with compaction between each lift, and–for some applications–a vibrating machine. Engineered fill self-compacts, with no need for dump trucks, backhoes, or workers to operate those machines or perform manual compaction.

Flowable fill also hardens within 90 minutes and is completely ready to go within 24 hours, saving 30-50% of overall construction time compared to traditional fill.

#3: Reduced material usage

Cellular grout contains uniform air bubbles trapped within the material itself, increasing the overall volume and requiring less cement to fill the same space. The lower amount of material required, in addition to its light weight, reduces freight and transportation expenses.

#4: Fewer crew members required

Flowable fill is easy to mix and install. Traditional fill may require a superintendent, dump truck operator, backhoe operator, and several laborers to man the vibrating compactors. For most low-density cellular concrete applications, only a superintendent, CDL driver, and one or two additional workers are needed.

#5: Improved durability and longevity

Flowable fill distributes loads evenly and effectively absorbs stress, extending the lifespan of structures and reducing lifecycle repair and maintenance costs.

#6: Easily excavatable

Flowable fill can be dug out by hand and does not require the use of pavement breakers. If you’re backfilling a utility trench, engineered fill will provide you easy access to the utility in the future if repairs are needed.

Want to learn more?

For questions about whether flowable fill is the right choice for your project, contact our team of experts.