Project Overview

Application: LWIC Roof Deck for Giglio Warehouse

General Contractor: Perkins Roofing

Services Provided: Lightweight Insulating Concrete Roof Deck System

Project Summary

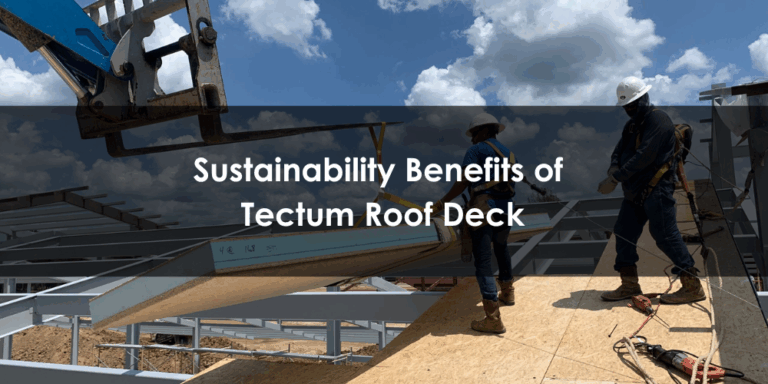

Giglio Distributing Company, a wholesale beverage distributor located in Beaumont, Texas, needed a new roof for their warehouse. The warehouse roof had run the full course of its lifecycle, and needed to be fully removed and replaced with a new roof system. The warehouse was located near a water source, and the total square footage was approximately 35,264 square feet.

The Problem

The Nettles team was approached by Perkins Roofing to provide a quote for re-roofing the warehouse using lightweight insulating concrete (LWIC) and providing slope to the gutter system. The warehouse roof needed positive drainage on all four sides, since the gutters were essential for disposing of rain water. The LWIC roof deck could provide good wind uplift and ensure proper drainage.

The Nettles Solution

The Nettles team was able to remove the worn-out roof and install an LWIC roof dec system. We provided a 1/8″ slope to the gutters using a EPS “Holey Boards” of various thicknesses, starting with 6″ x 4′ x 4′ Styrofoam boards. We then placed additional EPS insulation that increased 1″ every 8 feet, with the thickest EPS being 14″ thick, until the insulation reached the ridge line. This solution provided the owner a minimum R-value of 25, meeting code requirements, and an average R-value of 41.5

LWIC was an attractive solution for the new roof given its low weight. Weight is an important consideration for engineers, and LWIC can easily satisfy most load requirements. For this warehouse, the dead load was an average of 7psf, and Nettles LWIC roof decks range from 6.9-8.2psf.

The Nettles team was able to complete the project in five work days, including equipment set-up, pouring the slurry coat over the temporary membrane, placing the EPS insulation, clean-up, and breaking down of equipment. Less than 72 hours after installation, the roofing contractors were able to successfully apply the roof membrane over our monolithic LWIC surface.

Nettles is one of the largest and most respected subcontractors and installers of LWIC roof deck systems in the country. We work across the Midwest, including Texas, Oklahoma, Arkansas, Louisiana, Missouri, Kansas, the Dakotas, and more. To learn more, check out our other featured projects or get in touch with an expert.